Introduction

Selecting the ideal injection molding tooling is central to successful product manufacturing. Injection molding is an increasingly popular technique for producing plastic parts, and tooling selection has an immense effect on the quality, efficiency, and cost-efficiency of production. Tooling such as molds and associated components plays a critical part in shaping the final product. By understanding the significance of selecting appropriate injection molding tooling, manufacturers can ensure high-quality results while streamlining the manufacturing process and optimizing production capabilities. In this article, we will explore key considerations when choosing injection molding tooling for their specific product – giving valuable insights and guidelines to achieve successful outcomes.

II. Understanding Injection Molding process

Injection molding is a highly flexible and widely employed manufacturing method for producing plastic parts. It comprises several key components that work together to form the final product; let’s explore them more in-depth:

Plastic Resins:

Plastic resins are the raw materials used in injection molding. Available as pellets or granules, their properties may include strength, flexibility, heat resistance, and durability – which in turn may influence which resin will best meet the requirements of the final product.

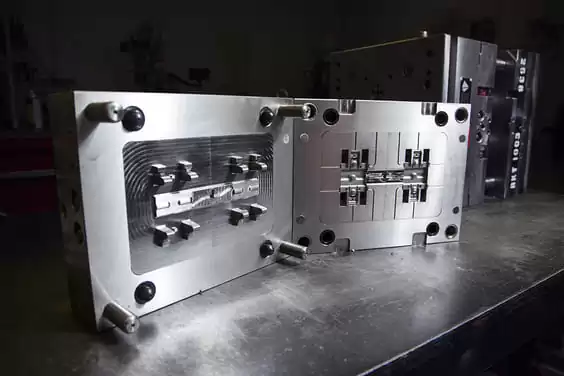

Injection Mold:

An injection molds is a custom-designed tool used to shape, size, and feature plastic parts. It consists of two halves: the cavity side (known as the cavity side in engineering jargon) and the core side. Molten plastic resin is then injected under high pressure into this cavity side to fill its structure forming the mold surfaces its desired part shape.

Injection Molders:

Injection molders (also referred to as injection molding machines) are equipment used for carrying out the injection molding process. They consist of a hopper to feed plastic resin into, a heating unit to melt it down, and an injection unit that pushes the liquid plastic into its molds. Furthermore, injection molders offer precise control over factors such as temperature, pressure, and injection speed to ensure accurate production results.

The injection molding process typically starts by heating and melting plastic resin in an injection molder. Once at its desired temperature, molten plastic is injected under high pressure into a mold cavity with high enough pressure that it solidifies within it, taking on its shape as it cools within. After cooling has occurred, the mold opens to release newly formed parts from within it.

Injection molding offers many advantages to manufacturers, including increased production efficiency, intricate part design capabilities, and the capacity to produce large volumes with consistent quality. By understanding the injection molding process and its key components, manufacturers can make informed decisions when selecting an injection molding tooling package tailored specifically to their product requirements.

III. Key Considerations for Tooling Selection

A.Understanding Your Product Requirements

To select the proper injection molding tooling, it is vital that you fully comprehend your product requirements. Please take into consideration these important elements:

Product Specifications: Provide detailed product specifications that detail its intended shape, dimensions, and features of interest to you.

Design Complexity: Take into consideration any intricate details, undercuts, or special surface finishes in your product’s design – these may include intricate details, undercuts, or special surface treatments that require closer examination.

Size and Scale: To select an optimal product size and scale that will dictate its tooling needs and production capabilities.

Material Selection: When selecting plastic material for use in your product, take into consideration its properties such as strength, flexibility, and chemical resistance.

Estimating Production Volume: To accurately plan for future production volumes and maximize efficiency in steel tooling, selection and manufacturing operations.

B.Working With Experienced Tooling Experts

Engaging experienced injection molding tooling experts or manufacturers is of great value in terms of both expertise and insight in areas like:

Design Optimization: Experienced tooling experts can ensure the design of your product for manufacturability, ensuring efficient production and cost-cutting measures.

Material Recommendations: They can assist you in selecting the optimal plastic material based on your product requirements, performance expectations, and cost considerations.

Tooling Feasibility: Professional tooling experts can evaluate the feasibility of your product design and suggest suitable tooling options to achieve desired outcomes.

C. Material Selection

Choosing the appropriate plastic material for your product is crucial. Consider the following factors when selecting the material:

- Required Properties: Identify the specific properties your product requires, such as strength, durability, chemical resistance, or heat resistance.

- Material Compatibility: Ensure the selected plastic material is compatible with the injection molding process and can be effectively processed.

- Cost Considerations: Evaluate the cost-effectiveness of the material, considering factors such as material availability, processing efficiency, and overall project budget.

D. Tooling Design

Effective tooling design is essential for successful injection molding. Consider the following factors:

- Part Geometry: Optimize the part design for injection molding, considering factors like wall thickness, rib design, and the presence of any critical features.

- Draft Angles: Incorporate appropriate draft angles to facilitate easy part ejection from the mold, reducing the risk of damage or deformation.

- Gate Location: Determine the optimal gate location for the injection point to ensure uniform filling of the mold and minimize potential defects.

- Ejection System: Design an efficient ejection system to safely remove the molded part from the mold without causing any damage.

- Mold Material: Select a suitable mold material based on factors such as expected production volume, material compatibility, and cost considerations.

By considering these key factors and working closely with experienced tooling experts, you can make informed decisions and select the right injection molding tooling for your specific product, leading to successful production outcomes.

IV. Answering Common Questions

aA.How Can I Select an Injection Molding Machine?

Selecting the ideal injection molding machine requires taking into account several key considerations, including:

Clamping Force: Select an appropriate clamping force depending on the size, weight, and complexity of the mold materials your product to ensure the machine can securely hold the mold during the injection.

Shot Size: To determine an efficient production, calculate and select a machine with an adequate shot capacity to accommodate the required material amount (shot size). This should ensure efficient production.

Machine Specifications: Consider factors like injection pressure, injection rate, and screw design when specifying your machine. These specifications must fit with both product requirements and characteristics of chosen plastic material.

B. How Can I Choose an Injection Molding Machine Size?

Determining the right injection molding machine size requires taking several factors into account:

Part Size and Weight: When selecting the clamping force necessary to secure your product, take into account both dimensions and weight to ensure the machine can effectively manage it.

Shot Size: To determine the volume of material required for each part, multiply its shot size by the number of cavities in your mold to calculate the total shot volume and ensure your machine has adequate shot capacity for production.

Cavity Quantity: Determine how many cavities your mold will contain. A higher production rate can be achieved with more cavities as multiple parts can be produced at once during each molding cycle. When making this decision, take into account your production volume requirements as well as any machine limitations which might prevent you from reaching this number of cavities.

C. How to Calculate Injection Molding Machine for a Specific Product?

To calculate the suitable injection molding machine for a specific product, follow these steps:

- Calculate Shot Volume: Determine the shot volume required for each part by considering its size and weight. Multiply the shot volume by the number of cavities in the mold to obtain the total shot volume.

- Select a Machine: Choose a machine with a shot capacity slightly higher than the calculated total shot volume. This ensures the machine can accommodate the required material volume for efficient production.

- Consider Other Factors: Besides shot volume, consider factors such as clamping force, injection pressure, injection rate, and screw design. These factors should align with the specific requirements of your product and the chosen plastic material.

D. What Tooling is Likely for Plastic Parts?

Common tooling materials for plastic parts include:

- Semi-Hardened Tool Steel: This material offers good durability and wear resistance. It is suitable for medium to high production volumes and can handle various plastic materials.

- Hardened Steel: Hardened steel provides excellent durability and longevity, making it ideal for high-volume production runs. It can withstand the demanding conditions of the injection molding process.

The choice of tooling material depends on factors such as the expected production volume, part complexity, material compatibility, and cost considerations. Consult with tooling experts to determine the most suitable aluminum tooling material for your specific plastic part production needs.

By addressing these common questions, you can gain a better understanding of the considerations involved in choosing the right injection molding machine and tooling materials for your product manufacturing process.

Conclusion

In conclusion, selecting the same material waste the right injection molding tooling is paramount for successful manufacturing. Throughout this article, we have explored the key considerations involved in this process. By understanding your product requirements, collaborating with experienced tooling experts, selecting appropriate materials, and optimizing tooling design, you can ensure high-quality production, cost-effectiveness, and efficient manufacturing.

Material selection plays a vital role in achieving the desired properties and performance of your product. Choosing the appropriate plastic material based on its properties and part requirements is essential for successful injection molding.

Tooling design factors, such as part geometry, draft angles, gate location, ejection system, and mold material, contribute to the overall quality and efficiency of production. Paying attention to these details ensures optimal performance and reduces the risk of defects or errors.

Furthermore, we addressed common questions regarding machine selection, determining machine size, calculating shot volume, and identifying suitable tooling materials for plastic parts. These insights provide clarity on the various aspects of tooling selection for injection molding.

Selecting the right injection molding tooling sets the stage for successful manufacturing. It ensures high-quality molded components, cost-effective production, and the ability to meet your product requirements. By considering all the factors discussed in this article, you can make informed decisions and optimize your manufacturing process.

Remember, collaboration with experienced tooling experts, a thorough understanding of your product requirements, appropriate material selection, and careful consideration of tooling design are key factors in achieving successful plastic injection molding outcomes. Invest time and effort into the tooling selection process to set the stage for a successful plastic injection molding project.