Introduction

Injection molding is a highly prevalent manufacturing process used to produce a wide range of plastic parts with accuracy and efficiency. However, designing molds for injection molding can be complex, as it requires careful consideration of various factors to ensure optimal part quality and manufacturing efficiency. This is where mold flow analysis plays a crucial role.

Mold flow analysis is a simulation-based technique that allows designers and engineers to predict and analyze the behavior of molten plastic within the mold cavity. By simulating the injection molding process, mold flow analysis provides valuable insights into material flow, cooling behavior, and potential defects. This information is vital for optimizing the mold design, selecting appropriate process parameters, and improving overall part quality.

Incorporating mold flow analysis in the manufacturing process offers several significant benefits. Firstly, it enables designers to identify and rectify potential issues upfront, resulting in improved part quality and reduced production costs. By understanding material flow, gate placement, and wall thickness distribution, designers can optimize the mold design to minimize defects such as weld lines, air traps, or sink marks.

Secondly, mold flow analysis enhances the overall efficiency of the design process. By simulating different scenarios and analyzing the results, designers can make informed decisions regarding mold cavity design, gate placement, and cooling channel configuration. This reduces the need for trial-and-error iterations, saving both time and resources during the design phase.

Lastly, incorporating mold flow analysis leads to enhanced manufacturing outcomes. By accurately simulating the injection molding process, manufacturers can optimize process parameters such as injection pressure, melt temperature, and cooling time. This results in improved cycle times, reduced scrap rates, and enhanced production efficiency.

In conclusion, mold flow analysis is of utmost importance in injection molding design. By leveraging simulation technology and analyzing material flow, gate placement, and cooling behavior, designers and engineers can optimize mold designs, enhance part quality, and streamline the manufacturing process. The benefits of incorporating mold flow analysis include improved part quality, reduced production costs, and enhanced overall manufacturing efficiency.

II. What is Mold Flow Analysis?

A. Definition and Explanation of Mold Flow Analysis

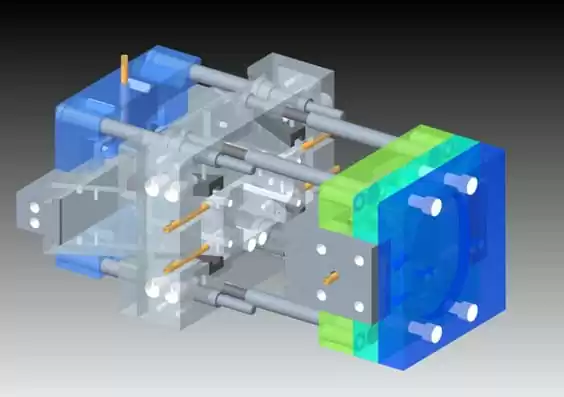

Mold flow analysis is a computer-aided simulation technique used in the field of injection molding to predict and analyze the behavior of molten plastic within a mold cavity. It involves utilizing specialized software to simulate the injection molding process and gain insights into various aspects such as material flow, cooling, pressure, and temperature distribution.

During mold flow analysis, the software utilizes mathematical models and algorithms to simulate the filling, packing, and cooling stages of the injection molding process. By analyzing the flow of molten plastic, the software can predict how the material will distribute within the mold, how it will cool and solidify, and how different design and process parameters will affect the final part quality.

B. Importance of Understanding Material Flow, Wall Thickness, and Gate Location

Understanding material flow is a crucial aspect of mold flow analysis. It allows designers to predict how the molten plastic will flow and fill the mold cavity, ensuring proper and uniform distribution. By analyzing material flow, designers can identify potential issues such as flow imbalances, air traps, or weld lines that may affect part quality. This understanding enables them to optimize the mold design and injection parameters for better material flow and overall part quality.

Wall thickness plays a significant role in mold flow analysis. Varied wall thicknesses can lead to uneven material flow, resulting in defects like sink marks, warpage, or incomplete filling. By considering wall thickness during mold flow analysis, designers can optimize the part geometry and wall thickness distribution to ensure consistent material flow and minimize potential defects.

Gate location is another critical factor in mold flow analysis. The gate is the entry point through which the molten plastic is injected into the mold cavity. The selection of an optimal gate location is essential for achieving proper filling, minimizing pressure drop, and avoiding cosmetic defects such as gate blush or jetting. Mold flow analysis helps designers identify the most suitable gate location, ensuring uniform material flow and optimal part quality.

In summary, mold flow analysis provides designers with a deeper understanding of material flow, wall thickness distribution, and gate location. By considering these factors during the analysis, designers can make informed decisions to optimize the mold design, improve part quality, and minimize production issues in the injection molding process.

III. Steps to Incorporate Mold Flow Analysis in Injection Molding Design

A. Step 1: Define Objectives and Material Selection

- Importance of Defining Objectives and Considering Material Properties

- Clearly define the objectives of the injection molding process, such as part quality, cycle time, and cost efficiency.

- Consider material properties like melt temperature, flow characteristics, and desired outcomes for the final product.

- Objectives and material selection provide the foundation for mold flow analysis.

- How Material Selection Affects the Mold Flow Analysis Process

- Different materials have distinct flow behaviors, shrinkage rates, and cooling characteristics.

- Material properties directly impact mold filling, cooling, and overall part quality.

- Proper material selection ensures accurate mold flow analysis and optimized design decisions.

B. Step 2: CAD Model Design and Wall Thickness

- Role of Accurate CAD Model Design in Mold Flow Analysis

- Create or import a 3D CAD model of the part with precise geometry representation.

- Ensure the CAD model accurately represents the desired part and includes all critical features.

- The accuracy of the CAD model directly impacts the reliability of the mold flow analysis results.

- Significance of Optimizing Wall Thickness for Uniform Material Flow

- Design the part with appropriate wall thicknesses to promote consistent material flow during injection molding.

- Uneven wall thicknesses can lead to flow imbalances, air traps, or shrinkage/warpage issues.

- Optimizing wall thickness improves material flow and helps achieve desired part quality.

C. Step 3: Gate Placement and Mold Cavity Design

- Importance of Gate Location for Effective Material Filling

- Selecting the optimal gate location is crucial for ensuring proper filling of the mold cavity.

- The gate determines how the molten plastic enters the mold and impacts material flow.

- Improper gate placement can result in flow imbalances, cosmetic defects, or inadequate packing.

- Considerations for Mold Cavity Design and Support Structures

- Design the mold cavity to accommodate the desired part geometry and ensure uniform material flow.

- Consider the need for support structures, such as ribs or ejector pins, for proper mold operation.

- Mold cavity design and support structures influence material flow and overall part quality.

D. Step 4: Run Mold Flow Analysis Using Mold Flow Analysis Software

- Overview of Mold Flow Analysis Software Options

- Utilize specialized software tools like Moldflow Insight, Moldex3D, or other mold flow analysis software.

- These software options provide advanced simulation capabilities for analyzing material flow behavior.

- Benefits and Capabilities of Software Simulation in Analyzing Material Flow, Cooling Behavior, and Potential Defects

- Mold flow analysis software simulates the injection molding process, providing insights into material flow, cooling, and defects.

- Analyze material flow patterns, temperature distribution, pressure drops, and potential defects like weld lines or air traps.

- Software simulation helps identify design issues and optimize the injection molding process for improved part quality.

E. Step 5: Design Optimization and Iteration

1.Making Design Modifications Based on Analysis Results

Analyze the results of mold flow analysis to identify areas for improvement.

Modify the mold design, including gate location, cooling channels, or wall thickness, to optimize part quality.

Iteratively repeat the mold flow analysis to validate the effectiveness of design modifications.

2.The Iterative Process of Refining the Mold Design Through Multiple Simulations

Refine the mold design by iteratively incorporating analysis feedback and making necessary adjustments.

Repeat the mold flow analysis after design modifications to validate improvements and ensure optimized results.

The iterative process helps achieve an accurate mold design for optimal injection molding performance.

F. Step 6: Validate and Verify

Importance of Validating Mold Flow Analysis Through Physical Tests or Comparison with Production Data

Perform physical tests on prototypes to validate the accuracy of the mold flow analysis results.

Compare the simulated results with actual production data to ensure the simulation represents real-world behavior.

Validation results guide further adjustments and improvements in the mold design and process parameters.

By following these steps, designers can effectively incorporate mold flow analysis into the injection molding design process, leading to improved part quality, reduced production costs, and enhanced overall manufacturing efficiency.

Conclusion

Incorporating mold flow analysis into the design process of injection molding is crucial for achieving high-quality and cost-effective production. By simulating the injection molding process and analyzing factors like material flow, wall thickness, and gate location, designers can optimize mold design, improve part quality, and reduce production costs. Mold flow analysis offers several key benefits that contribute to the overall success of the manufacturing process.

By utilizing mold flow analysis, manufacturers can optimize part quality by identifying and addressing potential defects such as weld lines, air traps, or sink marks. This leads to improved aesthetics and functionality of the final product. Additionally, the analysis helps in optimizing material flow, gate placement, and mold cavity design, ensuring uniform filling and minimizing defects.

Reducing production costs is another significant advantage of mold flow analysis. By identifying potential issues early on, manufacturers can make design modifications that optimize the injection molding cycle process, minimize material waste, and reduce the need for costly rework or iterations. This optimization leads to more efficient production, reduced scrap rates, and overall cost savings.

Mold flow analysis also saves valuable time during the design and production phases. By simulating different scenarios and analyzing the results, designers can make informed decisions upfront, eliminating the need for time-consuming trial-and-error iterations. This efficiency results in shorter development cycles and faster time-to-market for products.

In conclusion, incorporating mold flow analysis in the injection molding design process is essential for achieving high-quality parts, reducing production costs, and saving time. The benefits of mold flow analysis extend to improved part quality, optimized production processes, and enhanced overall manufacturing efficiency. Therefore, it is strongly encouraged for manufacturers to implement mold flow analysis as a valuable tool in their manufacturing processes. By leveraging this powerful analysis technique, manufacturers can achieve superior results in the highly competitive field of injection molding.