Introduction

Acrylic plastics, an integral component in the tapestry of contemporary fabrication, epitomizes the ingenuity and adaptability inherent in materials engineering. This methodology, centering around the manipulation of a translucent thermoplastic known as acrylic, has catalyzed a transformation across myriad sectors through its diverse applications. Fundamentally, acrylic injection molding machines involves the metamorphosis of acrylic material renowned for its durability and transparency – into a plethora of injection molded acrylic parts utilizing methods like injection molding, casting, and extrusion.

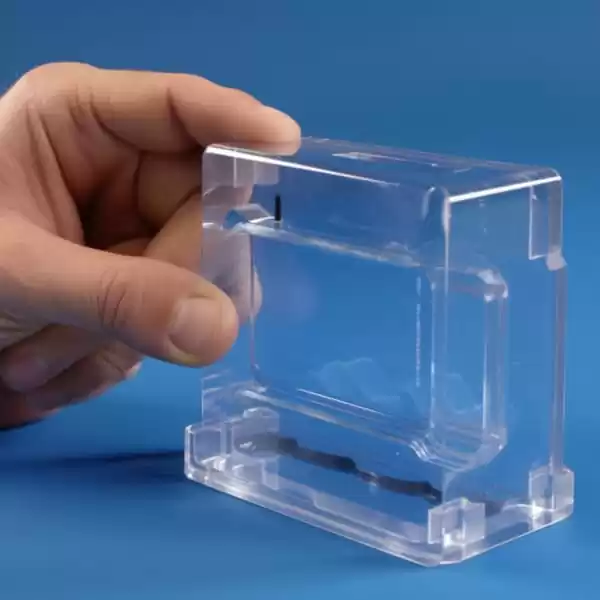

The prominence of acrylic in the arsenal of modern technology is monumental. Celebrated for attributes such as unparalleled optical lucidity, formidable impact resilience, and its malleability for shaping and molding, acrylic emerges as a nimble yet sturdy surrogate for glass and other traditional substrates. Its prowess in enduring environmental elements and thwarting UV radiation renders it an exemplary selection for exterior uses. Additionally, its aesthetic allure, manifested through a lustrous sheen and crystalline clarity, enhances its desirability in the spheres of design and visual display technologies.

Acrylic injection molding it’s utility is widespread, permeating sectors from medical safety shields to sophisticated automotive components. Its adaptability is evident in daily life, visible in domestic artifacts, signage, and even as a medium in artistic endeavors. The technique of sculpting acrylic – be it through injection molding for meticulously crafted parts or manual manipulation for bespoke artistic pieces – underscores the material’s flexibility and the creative evolution of manufacturing methodologies.

In this thorough dissection, we delve into the nuances of acrylic molding, revealing its methodologies, myriad uses, and its critical function in propelling modern technology forward. Traversing the domains of material science and industrial procedures, the perennial significance and burgeoning potential of acrylic materials in our technologically sophisticated world is unmistakably apparent.

What is Acrylic Molding?

1: Exposition and Synopsis

The craft of acrylic molding, a procedure vital in shaping thermoplastics into a myriad of shapes and entities, stands as a cornerstone in numerous sectorial activities. Acrylic, esteemed for its translucent nature, robustness, and adaptability, emerges as a preeminent selection. Diverse modalities exist for this molding, each aligning with distinct end-use scenarios and aesthetic criteria.

Diverse Modalities of Acrylic Molding

Injection Molding Method: This preeminent method excels in generating substantial quantities with uniform excellence, particularly tailored for intricate geometries.

Extrusion Molding: Optimal for fabricating extended, unbroken forms such as conduits and panels.

Casting Method: Employed in the creation of bulkier, irregular structures, frequently seen in creative pursuits.

Blow Molding: Predominantly utilized for the genesis of hollow items, including vessels and receptacles. Injection molding, in particular, shines with its meticulousness and capability to fabricate complex components on a large scale.

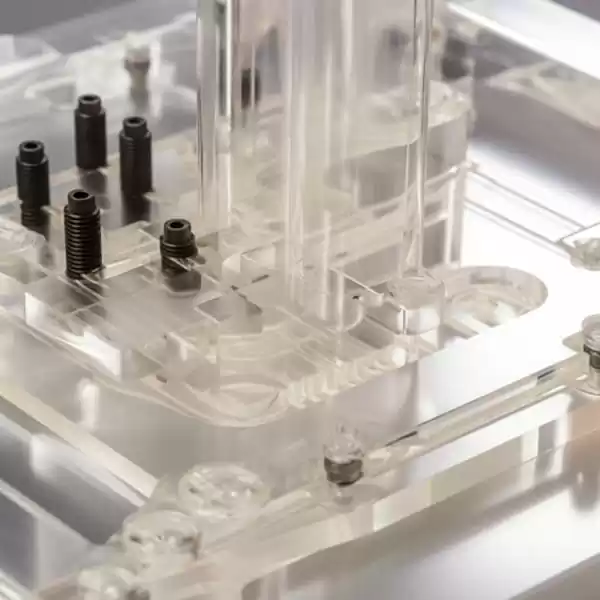

2: Intricacies of Acrylic Injection Molding

The acrylic injection molding sequence is an intricate yet potent technique for forging precise acrylic plastic components. It encompasses several pivotal phases:

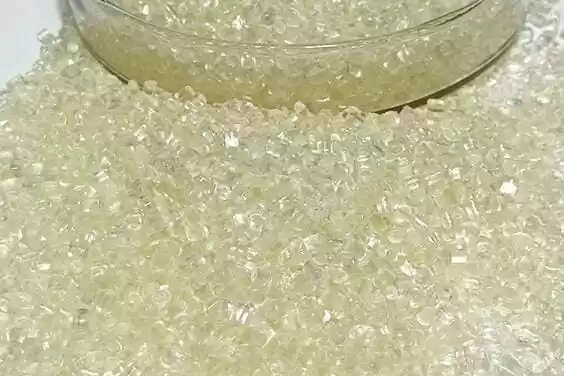

Preparatory Phase: Initial treatment involves drying acrylic substances (pellets acrylic sheets or granules) to eliminate moisture that could mar the quality of the end product.

Liquefaction: The dehydrated molten acrylic is introduced into the molding apparatus, where it is heated to a liquefied state.

Infusion: This molten substance is subsequently propelled into a pre-fabricated mold cavity with substantial pressure. This phase demands meticulous management of infusion velocity and pressure to guarantee uniform mold filling.

Cooling and Formation: Post-infusion, the acrylic commences cooling and shaping within the mold. The cooling phase is critical as it influences the structural soundness and exterior texture of the molded element.

Ejection: Following complete solidification, the component is dislodged from the mold, typically through an automated system within the machine.

Post-Molding Treatment: The ejected item might necessitate further refinement such as trimming redundant material, polishing, or applying a coat of paint.

Acrylic in Technology

In the realm of technological applications, the utility of acrylic substances spans a diverse array of sectors, underscoring its malleability and multifaceted nature.

Medical Devices

Within the medical sphere, the acrylic sheet is esteemed for its lucidity and sterility. Its deployment ranges from diaphanous incubators to components of surgical apparatus. Its innocuous composition and facility for sanitation render it optimal for clinical settings.

Consumer Products

Acrylic is prevalently employed in consumer goods, owing to its aesthetic allure and resilience. Ubiquitous objects encompassing spectacle lenses, fish tanks, and even furnishings utilize acrylic. Its capacity to emulate glass’s visage, coupled with enhanced sturdiness, elevates its status in domestic goods.

Superiority Over Alternative Materials

Weight: Acrylic’s reduced heft surpasses glass, facilitating easier manipulation and conveyance.

Machinability: Its susceptibility to shaping and molding permits more intricate designs than glass allows.

Cost-Effectiveness: Generally, injection molding acrylic is more economical to fabricate and mold compared to glass and certain other polymers.

Acrylic’s Advantages

Acrylic’s attributes not only foster versatility but also bestow it with a competitive advantage over diverse materials.

Optical Clarity

Acrylic’s exceptional light transmission rivals optical glass, maintaining clarity over time and resisting UV-induced discoloration.

Scratch Resistance

Though inferior to glass in hardness, acrylic resists scratches commendably and can be effortlessly polished if needed, making it a robust option for high-contact uses.

Impact Resistance

Acrylic’s resistance to impact far exceeds that of glass, diminishing shattering risks. This renders it a safer option for applications such as protective shields and windows.

Comparative Analysis with Other Materials

Versus Glass: Acrylic triumphs in lightness, impact resistance, and moldability, though it falls short in hardness.

Versus Other Polymers: In comparison to plastics like polycarbonate, acrylic offers unmatched clarity and UV resilience but is less sturdy upon impact.

Thermal Stability: Acrylic endures temperature fluctuations better than many polymers, preserving its characteristics across a broad thermal spectrum.

In summation, acrylic’s distinctive amalgamation of properties – such as optical clarity, resistance to scratches and impacts, and thermal stability – render it a material of choice in technological and consumer applications. Its amenability to various forms and configurations further amplifies its utility, evidencing acrylic as a substance that harmoniously integrates functionality with adaptability.

Key Factors in Acrylic Molding

Quintessential Elements in Acrylic Formation Techniques

The caliber of the end product in the realm of acrylic formation is contingent upon a myriad of elements, each playing a pivotal role in the overall efficiency and efficacy of the procedure.

Determining Elements Mold Configuration:

The architecture of the mold is of paramount importance. It necessitates consideration of acrylic’s contraction upon cooling, the trajectory of material flow, and the simplicity of dislodging the completed component. Intricate designs may demand more advanced mold configurations.

Substance Characteristics:

The specific grade and variant of acrylic utilized can markedly influence the end result. Attributes such as viscosity, fusion point, and thermal deformation temperature are crucial for selecting the appropriate substance for distinct applications.

Thermal Deformation Temperature:

This parameter indicates the heat level at which a material begins to deform under a predetermined burden. It is critical in ascertaining the conditions suitable for the usage of the acrylic item.

Fusion Point:

The fusion point of acrylic is a critical factor that must be meticulously regulated during the formation process to avert material deterioration and guarantee a superior finish.

Obstacles and Remedies in Acrylic Molding

Acrylic molding, much like any manufacturing process, faces its own array of distinct challenges. Successfully overcoming these obstacles is crucial for maintaining both the quality and efficiency of the end product.

Key Challenges Deformation and Shrinkage:

As acrylic cools, it’s susceptible to warping or shrinking, which can cause deformities in the final product.

Surface Imperfections:

During the molding process, issues such as bubbles or scratches may emerge, affecting both the visual appeal and functional quality of the product.

Stress Cracking:

Acrylic is prone to stress cracking, especially when exposed to certain chemicals or under continuous stress.

Effective Solutions and Best Practices Precision Mold Design:

Utilizing molds that are specifically designed to accommodate the unique properties of acrylic can help reduce deformation and shrinkage.

Controlled Cooling Techniques:

Implementing a gradual and controlled cooling process can decrease the chances of stress cracking and warping.

Selecting Appropriate Materials:

Choosing the right type of acrylic for the intended application can prevent many problems associated with its properties.

Surface Treatment Methods:

Applying protective coatings or conducting post-process polishing can help minimize surface imperfections.

Regular Stress Testing:

Conducting frequent tests for stress resistance can help identify potential issues early in the manufacturing process.

In conclusion, achieving success in acrylic molding requires a thorough understanding of both the material properties and the technical aspects of the molding process. By focusing on these critical factors and implementing effective solutions to common challenges, manufacturers can ensure the production of high-quality acrylic products that meet the desired specifications and performance standards.

Conclusion

Delving into the domain of contemporary manufacturing and technological innovation, acrylic and acrylic injection molding process, emerges as a pivotal element. Its significance is underscored by the material’s versatility, robustness, and visual allure. The art of sculpting acrylic, especially through the method of injection molding process, has unlocked novel pathways in diverse arenas, encompassing medical apparatuses to consumer commodities.

Looking ahead, the prospects for acrylic molding are luminous and optimistic. As we advance technologically, we anticipate the advent of more streamlined and precise molding methodologies. Such progress is poised to broaden the spectrum of acrylic’s applications, potentially catalyzing groundbreaking strides in realms like sustainable energy, aeronautics, and biomedicine.

Furthermore, ongoing explorations in the sphere of material sciences may yield novel acrylic concoctions boasting augmented characteristics, such as heightened thermal resistance or enhanced ecological compatibility. These strides are destined to further cement acrylic’s status as a preferred material in both established and emerging markets.

Acrylic’s malleability also paves the way for more eco-conscious endeavors. Amid escalating ecological apprehensions, the emphasis may transition towards the fabrication of recyclable acrylic substances or more energy-efficient molding techniques, harmonizing with worldwide environmental objectives.

In summation, the evolution of acrylic molding from a rudimentary manufacturing technique to a pivotal force in technological progression epitomizes its adaptability and potential. As we progress, acrylic molding is destined to assume a more critical role in the sculpting of our technological future, with boundless prospects ripe for discovery.