Introduction

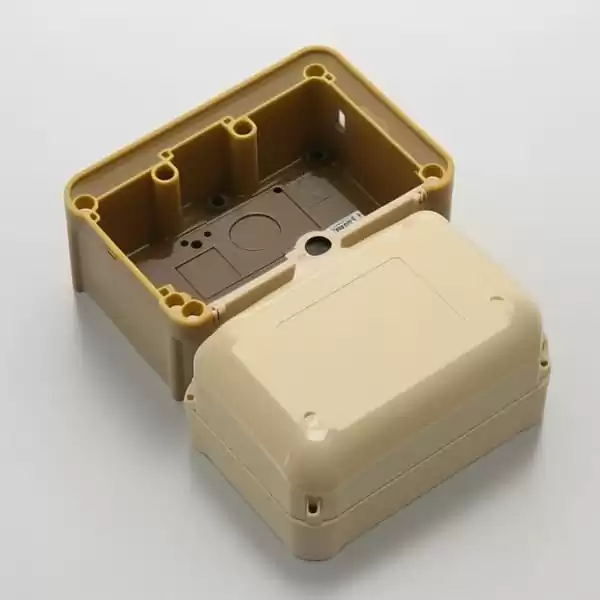

Injection moulding, a quintessential method in the realm of plastic injection molded part and fabrication, stands as a paragon of efficiency and ubiquity. This process entails the transference of molten plastic into a mold’s cavity, where it undergoes a metamorphosis, cooling and solidifying into the envisaged end product. Celebrated for its proficiency in generating substantial quantities of components with unwavering quality and exactitude, injection moulding is a cornerstone in diverse sectors, from the automotive industry to consumer product creation.

However, the technique is not devoid of impediments. A recurrent complication in injection moulded items is the emergence of sidewall indentations. These blemishes, depressions on the surface, potentially mar not only the visual allure but also the structural soundness of the items. This predicament is especially rampant in components with heterogeneous wall thickness, intricate shapes, or when utilizing certain plastic varieties. Comprehending and remedying the origins of these sidewall indentations is imperative for manufacturers committed to upholding elevated quality and standards in their offerings. To address this conundrum, an in-depth examination of various facets of the injection moulding process is required, including mold architecture, material choice, and procedural parameters.

The ensuing discourse delves into the complexities of injection moulding, unearths the fundamental reasons behind sidewall indentations, and deliberates on sophisticated strategies to counteract this prevalent yet pivotal concern.

Common Queries Addressed

Why Do Sidewall Dents Occur?

One of the most prevalent concerns in the realm of injection molding is the occurrence of sidewall dents. These imperfections are not merely cosmetic; they can significantly impact the structural integrity of the final product. Several factors contribute to this issue:

Mold Cavity Design:

The design of the mold cavity plays a pivotal role. Inadequate or improper design can lead to uneven pressure distribution during the injection process, causing dents.

Wall Thickness Variations:

Products with uneven wall thicknesses are particularly susceptible to dents. Thicker sections cool slower than thinner ones, leading to differential shrinkage and, consequently, dents in the final product.

Cooling Process:

The cooling process is another critical factor. Inconsistent or inadequate cooling can result in plastic parts, that are not uniformly solidified, leading to weak spots that manifest as dents.

Addressing these issues requires a thorough understanding of mold design, careful control of wall thickness, and optimization of the cooling process.

How Does Material Choice Affect the Outcome?

The choice of plastic material used in injection molding significantly influences the quality and characteristics of the final product. Different plastic materials react differently under the stresses of the molding process:

Semi-Crystalline Plastic materials:

These materials, such as polyethylene and polypropylene, have a more ordered molecular structure. They tend to shrink more relatively weak surface upon cooling, which can contribute to the formation of dents if not properly managed.

Non-Crystalline Plastics:

Materials like polystyrene and PVC, which do not have a regular molecular structure, exhibit different shrinkage and cooling behaviors. Understanding these differences is crucial in predicting and preventing defects like sidewall dents.

Selecting the right material not only involves understanding its properties under different molding conditions but also how it interacts with the design elements of the mold and the specific requirements of the product being manufactured.

In summary, sidewall dents in injection molded products can be attributed to a variety of factors, including mold design, wall thickness, cooling processes, and material properties. Addressing these aspects is key to producing high-quality, defect-free injection molded parts.

Key Factors in Injection Molding

In the realm of injection molding, the interplay of wall dimensionality and shrinkage phenomena is paramount. The girth of the walls profoundly impacts the cooling kinetics and dimensional contraction of a molded part. Parts with more substantial wall breadth exhibit slower thermal dissipation, culminating in heightened contraction when juxtaposed with their slender counterparts. This disparity in cooling rates can engender nonuniform shrinkage, frequently manifesting as indentations on the sidewalls. Furthermore, the thermal dilation characteristics of the polymer material wield considerable influence cooling shrinkage. During the thermal cycles of heating and cooling, the material undergoes expansion and contraction, potentially aggravating shrinkage irregularities and leading to surface imperfections if not meticulously regulated.

The architecture of the mold, with special attention to the cavity and surface design, is crucial in fabricating a product of superior caliber. An adeptly crafted mold ensures homogenous cooling and fluid dynamics of the material, diminishing the probability of indentation formation. The cooling apparatus within the mold must strike a delicate balance, sufficiently robust to uniformly temper the part, yet restrained enough to prevent hasty solidification and consequent flaws. The strategic distribution of cooling conduits and a holistic appraisal of the thermal equilibrium within the mold are essential to mitigate shrinkage-related quandaries.

Several pivotal process parameters substantially influence the outcome of injection molded artifacts:

Injection Pressure: Calibration of this parameter is essential to guarantee uniform and complete occupancy of the mold cavity by the molten polymer. Excessive pressure might invoke structural stress and distortion, whereas insufficient pressure could result in partial filling and the emergence of indentations.

Mold Temperature: Maintaining a consistent and optimal temperature of the mold is vital for modulating the cooling rate and dimensional reduction of the plastic. It should be sufficiently elevated to facilitate material flow, yet not excessively high to prolong the cooling phase unduly.

Cooling Surface: The design and efficacy of the cooling interface within the mold directly impact the rate and uniformity of part cooling. This aspect is particularly critical in thicker sections of the piece, where slower cooling might culminate in surface indentations.

Solutions and Strategies

In the realm of enhancing the surface of injection molded side products and diminishing the occurrence of sidewall imperfections, a multifaceted approach is imperative:

Refinement of Process Dynamics

Striving for an optimal synthesis of injection force and momentum is essential. Excessive force or rapidity may instigate structural compromise and indentations, while insufficient application can lead to inadequate cavity occupancy. The objective lies in discovering an ideal harmony where the plastic, in its molten state, fills the cavity holding pressure mold effectively, eschewing flaws.

Uniformity in Injection Molding Sequences

The pursuit of uniformity in the injection molding sequences is a cornerstone for stability in production, yielding a diminution in variability and flaws in the end product.

Material and Design Considerations

The judicious selection of materials coupled with a well-considered mold design are pivotal in staving off sidewall depressions:

Opting for Fortified Materials: Utilizing materials fortified or possessing enhanced thermal endurance can more robustly endure the rigors of the injection molding process, thereby lessening the emergence of dents and other distortions.

Modifications in Mold Architecture: Tailoring the mold to align with the specific traits of the plastic material is crucial. This encompasses the strategic layout of cooling conduits, the mold wall thickness, and the comprehensive design to ensure homogenous cooling and material distribution.

Advanced Methodologies

Adopting avant-garde techniques can significantly elevate the caliber of injection molded products:

Optimal Temperature Regulation: It is critical to maintain both mold and material temperatures within ideal ranges, encompassing not just the molten plastic but also the mold’s own temperature. Consistent temperature control is instrumental in achieving uniform cooling and mitigating shrinkage-induced issues.

Augmentation of Cooling Efficacy: Enhancing the cooling system’s efficiency within the mold is vital in addressing shrinkage. Efficient cooling assures appropriate cooling rates, thus reducing the likelihood of shrinkage that results in sidewall indentations.

The implementation of these methodologies and strategies can markedly elevate the quality of injection molded products, curtailing the frequency of sidewall dents and other associated anomalies. This approach integrates a blend of process condition optimization, meticulous material selection, mold design for peak efficiency, and the application of advanced techniques for temperature and cooling management.

Solutions and Strategies

Optimizing Process Conditions

Achieving high-quality injection molded products with minimal sidewall dents necessitates the optimization of various process conditions:

- Balancing Injection Pressure and Speed: A delicate balance between injection pressure and speed is key. Too high a pressure or too fast a speed can cause stress and deformation, leading to dents. Conversely, too low pressure or slow speed might result in insufficient filling of the mold cavity. The goal is to find the perfect equilibrium where the molten plastic fills the mold effectively without causing defects.

- Consistent Injection Molding Cycles: Consistency in the injection molding cycles ensures stability in the production process, leading to fewer variations and defects in the final products.

Material and Design Considerations

Selecting the right materials and thoughtful design of the mold are critical in preventing sidewall dents:

- Choosing Reinforced Materials: Materials that are reinforced or have higher temperature resistance can better withstand the stresses of the injection molding process. This resistance can reduce the occurrence of dents and other deformities.

- Adjustments in Mold Structure: Designing the mold to accommodate the specific characteristics of the plastic material is vital. This includes optimizing the layout of cooling channels, the thickness of the mold walls, and the overall design to ensure even cooling and material flow.

Advanced Techniques

Implementing advanced techniques can further enhance the quality of injection molded plastic products:

Managing Temperature Within Optimal Ranges: Maintaining the mold and material temperature within optimal ranges is crucial. This involves not just the temperature of the molten plastic, but also the temperature of the mold itself. A well-regulated maximum and minimum temperature helps in achieving uniform cooling and reduces shrinkage-related issues.

Enhancing Cooling Efficiency: Improving the efficiency of the cooling system in the mold plays a significant role in addressing molding shrinkage. Effective cooling ensures that the molded part cools down at the right rate, minimizing the chances of shrinkage that leads to sidewall dents.

Conclusion

Confronting the conundrum of sidewall indentations in products crafted through injection molding is a complex challenge necessitating a holistic and comprehensive strategy. Our investigation reveals that these indentations are not merely cosmetic imperfections but can profoundly influence the functional and structural soundness of the end product. Tackling this predicament demands an in-depth cognizance of the entire injection molding odyssey, encompassing the subtleties of material characteristics, mold architecture, and procedural conditions.

The quintessence of averting sidewall indentations resides in an exhaustive scrutiny of each phase in the injection molding journey. This scrutiny mandates meticulous selection of materials, ensuring the chosen polymers not only fulfill the end product’s specifications but also exhibit predictable behavior under the distinct conditions of molding. The mold’s design is equally pivotal; a mold thoughtfully crafted to accommodate the thermal expansion and fluid dynamics of the plastic can markedly diminish defect occurrences.

Moreover, the fine-tuning of procedural variables like injection force, mold temperature, and cooling efficacy is paramount. These elements require precise adjustment to harmonize the material’s flow and cooling, thereby curtailing the likelihood of uneven contraction and persistent strains that culminate in sidewall indentations.

In summary, eradicating sidewall indentations in injection molded products is less about isolating a single component of the process and more about amalgamating all facets into a unified, efficiently managed system. Manufacturers devoted to comprehending and refining each segment of the injection molding process will witness notable enhancements in product quality. This not only augments the aesthetic allure and utility of the products but also bolsters the manufacturer’s reputation for excellence and dependability, a crucial edge in the fiercely competitive realm of manufacturing.