Introduction

Plastic injection molding is an increasingly popular manufacturing technique that involves injecting molten plastic material into molds in order to create specific shapes. This method has become an indispensable resource in numerous industries such as automotive, aerospace, medical and consumer goods manufacturing processes – and plastic molding offers numerous advantages over more traditional processes for producing plastic parts. Here we explore its environmental impacts, manufacturing advantages and the process’s versatility when used to produce complex parts.

II: Plastic Injection Molding Process

Injection Molding Process and Its Key Components

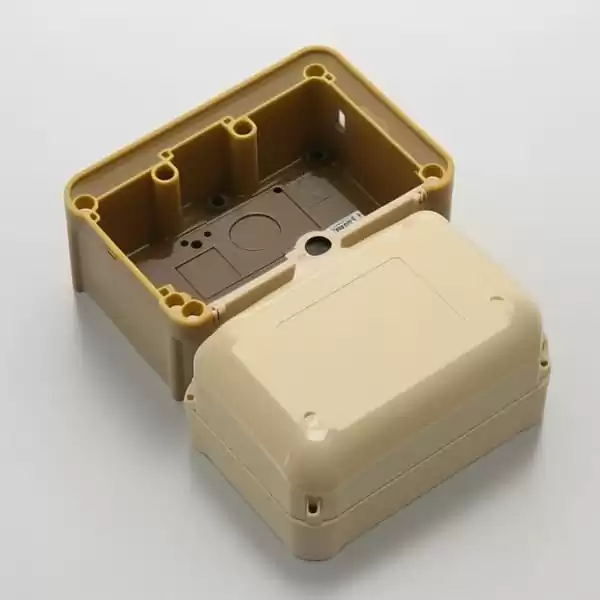

Injection molding is an extremely precise manufacturing process involving melting plastic material and injecting it under high pressure into mold cavities. Once inside, the plastic cools and solidifies, producing a final product which takes the shape of its mold.

Injection molding entails three key components, the injection unit, mold and clamping unit. The injection unit is responsible for melting and injecting plastic material into the mold while its steel construction helps determine its shape; finally, clamping ensures it remains closed during injection processes and applies pressure as required to keep it shut.

Injection Molding advantages

As opposed to traditional manufacturing processes, injection molding offers many distinct advantages over their counterparts. One such benefit is being able to produce complex parts with high precision and tight tolerances at lower cost; as well as producing multiple parts at once for cost-effective mass production; furthermore it produces consistent quality parts, decreasing defects or errors and making production faster overall.

Plastic material offers many advantages for injection molding. Plastic is lightweight yet sturdy material that can be formed into various shapes and sizes without breaking. Furthermore, its recycling can reduce environmental impacts associated with manufacturing.

Overall, injection molding with plastic material offers many advantages to manufacturers, making it a popular choice for creating plastic parts of various kinds.

III. Environmental Benefits

Plastic injection molding has a positive impact on the environment compared to waste plastic typically due to traditional manufacturing processes. One of the primary reasons for this is the ability to recycle and reuse waste plastic. During the injection molding process, any unused or waste plastic is typically ground up and reused in future molding runs, reducing the amount of plastic waste produced.

In addition to recycling, plastic injection molding also offers benefits in terms of energy consumption. The process requires less energy compared to traditional manufacturing processes, such as machining or casting. This means that less fossil fuel is burned to produce the same amount of parts, resulting in a lower carbon footprint.

Another way that plastic injection molding benefits the environment is through the safe combining of plastics. By carefully selecting and combining plastic materials in the injection molding process, manufacturers can minimize waste and reduce the environmental impact of plastic production. For example, by combining different types of plastic with complementary physical and chemical properties, the resulting parts can be stronger, more durable, and require less material overall.

Overall, plastic injection molding offers a number of environmental benefits through its ability to recycle waste plastic, consume less energy, and minimize waste through careful material selection. By continuing to focus on sustainable manufacturing practices and innovative solutions for waste reduction, the industry can further reduce its environmental impact and continue to provide high-quality plastic parts for a variety of applications.

IV. Injection Molding Advantages

Injection molding is an efficient manufacturing method with numerous benefits for producing plastic parts.

One of the primary benefits of injection molding is its ability to produce complex parts with consistent quality and tight tolerances, with high precision molding processes yielding identical and repeatable parts – an especially significant advantage in industries like aerospace and medical where precision is key.

injection molding offers several distinct advantages over its alternatives for high-volume production runs, including its cost-efficiency. Machines designed specifically for high volume injection molding, can quickly produce large numbers of parts – making this method the ideal option for mass production.

Injection molding can produce plastic components with properties similar to metal ones – strength and durability are particularly similar – thus replacing metal components in many applications. Furthermore, injection molded parts often weigh less than their metal counterparts which results in increased fuel efficiency for applications like the automotive industry.

Plastic injection molding offers many advantages, including its ability to produce complex parts consistently with high production output rates and versatility in replacing metal components in various applications with plastic parts. As such, injection molding has become an attractive and cost-effective solution for producing various plastic parts.

V. Benefits for Manufacturers

Plastic injection molding offers a variety of benefits for manufacturers, including cost savings and the use of current leading-edge technologies.

One major advantage of injection molding is the ability to reduce manufacturing costs. The process allows for high volume molding runs with minimal labor costs, making it a cost-effective option for producing large quantities of parts. Additionally, injection molding equipment can operate for long periods without requiring maintenance, further reducing costs for manufacturers.

Aligning plastics in the mold is also an important aspect of injection molding and production process that can result in faster production cycles and virtually identical parts. The plastic material must be aligned correctly within the mold to ensure that the final product meets the required specifications. This process can be automated, resulting in faster production cycles and virtually identical parts.

The use of current leading-edge technologies in injection molding is also critical in producing even the most complex plastic parts. Technologies such as 3D printing and computer-aided design (CAD) can help manufacturers design injection molding components with greater precision and accuracy, resulting in parts that are consistent and of higher quality. These technologies also enable manufacturers to quickly make changes to designs, reducing lead times and increasing flexibility.

Overall, the benefits of plastic injection molding for manufacturers include cost savings, faster production cycles, and the ability to use current leading-edge technologies to produce high-quality plastic parts. By continually improving and innovating within the injection molding process manufacturers can remain competitive and meet the demands of a rapidly changing marketplace.

Conclusion

Plastic injection molding is an efficient manufacturing method with numerous advantages for producing plastic parts. With low costs, high output production rates, and virtually automatic processes making this cost-effective solution ideal for mass production of multiple parts at once.

Plastic injection molding offers several advantages when it comes to product quality, such as its ability to create parts that withstand even the harshest environments and provide smooth surface finishes and sharp edges resulting in products that meet their respective specifications.

Plastic injection molding is an eco-friendly manufacturing method that reduces waste through its use of recycled plastic material and careful selection of plastic materials, which results in a lower carbon footprint compared to traditional manufacturing processes.

Plastic injection molding offers many advantages for manufacturers, including cost savings, high production output, product quality and sustainability. By continuing to innovate and perfect their injection molding processes, manufacturers can remain competitive and meet the requirements of an ever-evolving marketplace.