Introduction

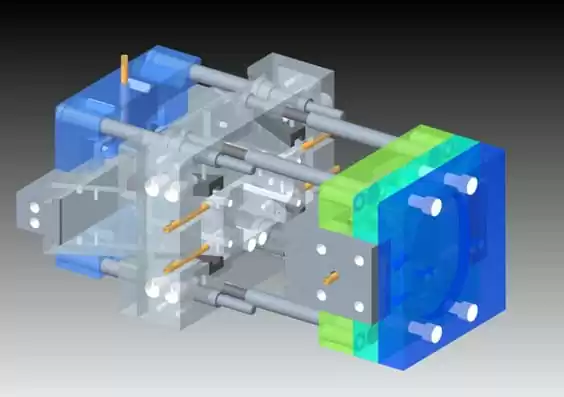

At the core of injection molding lies mold design – an essential factor which has an immense influence over quality, efficiency and cost-effectiveness of plastic component production. We will discuss in this article which are some key considerations engineers and designers must bear in mind when creating an injection mold that ensures production of high-quality plastic injection molded parts.

Key factors to be discussed:

Part Design: After assessing all part requirements, including wall thickness, nominal wall thickness, sharp corners, rounded corners and consistent wall thicknesses; designing parts for injection molding with maintain uniform wall thickness and appropriate draft angle will help ensure material flow without defects such as sink marks or flaking.

Material Selection: When selecting materials for injection molded part, careful evaluation is key to achieving optimal results. Careful consideration must be given when comparing common injection molding materials such as ABS or PLA.

Cooling System: Establishing an effective cooling system during injection molding is crucial to increasing cycle times, minimizing warping, and improving part quality. An efficient cooling system will improve cycle time while at the same time decreasing cycle times and warping.

Venting: Ensuring an appropriate level of venting within the mold allows gases to escape during injection molding, helping eliminate cosmetic defects and maintain consistent wall thicknesses. Adequate venting will also ensure more accurate results from injection molding manufacturing process.

Employing these key considerations during mold design allows manufacturers to achieve optimal results in terms of part quality, production efficiency and cost-effectiveness. We will explore each factor further in this article while offering insights for improving the design process.

Essential Factors to be Considered for Mold Making

Part design plays a crucial role in moldability and ultimately affects the quality of injection molded part. Here are the key factors to consider:

Importance of Part Design:

Proper part design is fundamental to successful mold making. It involves analyzing the part requirements, including its dimensions, complexity, and functionality. A well-designed part ensures efficient material flow during the injection molding process and minimizes the risk of defects. It is essential to understand the intended use of the part and any specific performance requirements.

Significance of Wall Thickness:

Wall thickness is a critical factor in injection molding. It impacts part strength, cooling time, and material flow. Designing walls with uniform thickness is preferable to ensure consistent part quality. Deviations in wall thickness can lead to issues like sink marks or warping. Optimal wall thickness varies depending on the part’s size, geometry, and material.

Importance of Nominal Wall Thickness:

Nominal wall thickness refers to the intended or desired thickness of a part. It serves as a reference point during the mold design process. Deviations from the nominal wall thickness can occur due to various factors, such as material shrinkage. Maintaining consistent wall thickness throughout the part helps prevent defects and ensures structural integrity.

Impact of Sharp Corners and Rounded Corners:

Sharp corners in part design can lead to stress concentration, which may result in part failure or cosmetic defects. Rounded corners are preferred as they distribute stress more evenly, improving the overall strength and appearance of the part. Additionally, rounded corners facilitate material flow during the injection molding process, reducing the risk of flow-related defects.

Need for Consistent Wall Thickness and Appropriate Draft Angles:

Consistency in wall thickness is crucial for uniform material flow and proper filling of the mold cavity. Variations in wall thickness can cause uneven cooling, warping, or sink marks. Furthermore, incorporating appropriate draft angles in the part design allows for easy ejection from the mold. Draft angles reduce friction and enable smooth release of the part, preventing damage and ensuring efficient production.

By considering these factors during part design, manufacturers can optimize moldability, minimize defects, and enhance the overall quality of injection molded parts

II. Material Selection for Injection Molded Parts

Selecting the right material for injection molding is of utmost importance as it directly impacts the performance, appearance, and structural integrity of the final parts. Consider the following factors when choosing the material:

Importance of Material Selection:

The material chosen for injection molded parts significantly influences their mechanical performance, cosmetic surface quality, and overall structural integrity. Different materials possess varying properties such as strength, flexibility, heat resistance, chemical resistance, and aesthetics. The material should be compatible with the intended application and meet the desired specifications.

Considerations for Material Selection:

a. Mechanical Performance:

Assess the mechanical requirements of the part, including factors like load-bearing capacity, impact resistance, and dimensional stability. The material should have suitable mechanical properties to withstand the intended use and environmental conditions.

b. Cosmetic Surface:

Consider the desired surface finish, texture, and appearance of the part. Some applications may require a smooth, glossy surface, while others may necessitate a textured finish for improved grip or aesthetics. The material should be capable of achieving the desired cosmetic surface quality.

c. Structural Integrity:

Evaluate the structural requirements of the part, such as rigidity, durability, and dimensional accuracy. The material should provide the necessary strength and structural integrity to ensure the longevity and functionality of the part.

Common Injection Molding Materials:

There is a wide range of materials suitable for injection molding. Some common examples include:

Thermoplastics: Such as polypropylene (PP), polyethylene (PE), polystyrene (PS), acrylonitrile butadiene styrene (ABS), and polycarbonate (PC).

Engineering Plastics: Including nylon (PA), polyethylene terephthalate (PET), polybutylene terephthalate (PBT), and polyphenylene sulfide (PPS).

Specialty Plastics: Such as polyether ether ketone (PEEK), liquid crystal polymers (LCP), and polyetherimide (PEI).

Need for Careful Material Evaluation:

Selecting the appropriate material requires careful evaluation. Factors to consider include material properties, processing characteristics, cost, availability, and regulatory compliance. Conduct thorough material testing, consult material data sheets, and seek advice from material suppliers to ensure the chosen material meets the specific requirements of the injection molded parts.

By carefully considering material properties and evaluating the specific needs of the injection molded part, manufacturers can make informed decisions in selecting the most suitable material for achieving desired mechanical performance, cosmetic surface quality, and overall structural integrity.

III. Key Features of Injection Molding process control

At the core of injection molding lies mold design – an essential factor which has an immense influence over quality, efficiency and cost-effectiveness of plastic component production. We will discuss in this article which are some key considerations engineers and designers must bear in mind when creating an injection mold that ensures production of high-quality parts.

Key factors to be discussed:

Part Design:

After assessing all part requirements, including wall thickness, nominal wall thickness, sharp corners, rounded corners and consistent wall thickness; designing parts with uniform wall thickness and appropriate draft angles will help ensure material flow without defects such as sink marks or flaking.

Material Selection:

When selecting materials for injection molded parts, careful evaluation is key to achieving optimal results. Careful consideration must be given when comparing common injection molding materials such as ABS or PLA.

Cooling System:

Establishing an effective cooling system during injection molding is crucial to increasing cycle times, minimizing warping, and improving part quality. An efficient cooling system will improve cycle time while at the same time decreasing cycle times and warping.

Venting:

Ensuring an appropriate level of venting within the mold allows gases to escape during injection molding, helping eliminate cosmetic defects and maintain consistent wall thickness. Adequate venting will also ensure more accurate results from injection molding processes.

Employing these key considerations during mold design allows manufacturers to achieve optimal results in terms of part quality, production efficiency and cost-effectiveness. We will explore each factor further in this article while offering insights for improving the design process.

IV. Key Variables in Injection Molding:

Injection molding involves several key variables that significantly impact the quality and efficiency of the process. Consider the following variables:

Importance of Temperature Control:

Temperature control is crucial in achieving consistent and high-quality results in injection molding. Proper control of the melt temperature and mold temperature ensures optimal material flow, proper filling of the mold cavity, and uniform cooling. Variations in temperature can lead to defects such as warping, sink marks, or inconsistent part dimensions. Precise temperature control is essential to maintain the desired material properties and part quality throughout the production process.

Significance of Optimizing Injection Pressure and Injection Speed:

Optimizing injection pressure and injection speed are vital for successful injection molding. Injection pressure determines the flow of the molten material into the mold cavity. Proper optimization ensures complete filling of the cavity, uniform part dimensions, and minimized defects like voids or short shots. Injection speed affects the filling pattern, material flow, and cooling rate. Careful control of injection speed is necessary to prevent issues like flow hesitation, flow marks, or flash. Balancing injection pressure and speed is crucial to achieve optimal part quality and minimize cycle time.

Importance of Time Management in Overall Cycle Time:

Time management plays a critical role in the overall cycle time of the injection molding process. The cycle time includes injection, cooling, and ejection of the part from the mold. Efficient time management ensures maximum productivity and cost-effectiveness. Reducing cycle time improves production efficiency, increases throughput, and lowers manufacturing costs. It requires careful optimization of process variables, such as cooling time, mold open/close time, and ejection time, while maintaining the desired part quality.

By effectively controlling temperature, optimizing injection pressure and speed, and managing the overall cycle time, manufacturers can achieve consistent and high-quality injection molded parts. These key variables are interdependent and require careful adjustment and monitoring during the production process. Precise control and optimization contribute to improved part quality, reduced scrap rates, enhanced productivity, and cost savings in injection molding operations.

Conclusion:

Designing an injection mold requires an in-depth knowledge of all of the key factors affecting quality and efficiency in injection molding processes. Multiple aspects must be assessed throughout this design phase in order to reach optimal results.

Design of injection molded parts plays a pivotal role in moldability and overall quality. Considerations must include wall thickness, nominal wall thickness, sharp corners, rounded corners and consistent wall thickness to ensure proper material flow, avoid defects and uphold structural integrity.

Material selection is another essential factor that directly impacts mechanical performance, cosmetic surface quality and structural integrity of injection molded parts. Careful consideration must be given to material properties, processing characteristics, cost considerations and compliance requirements when selecting suitable material for these injection molded parts.

Process control is critical to producing consistent and high-quality injection molding results. Temperature management ensures proper material flow and avoids defects; optimizing injection pressure and speed enable complete filling without defects; while managing cycle times improves productivity and cost-efficiency.

As part of the design process, continuous evaluation and optimization are of great importance. Assessing part requirements carefully, choosing an ideal material choice and fine-tuning process variables are all vital parts of producing high-quality injection molded parts.

By paying careful attention to part design, material selection and process control in their injection molding operations, manufacturers can achieve efficient production, superior part quality and significant cost savings through injection molding operations.

Careful consideration, evaluation and constant optimization of mold designs is integral to their success.