Just Tell us Your Idea, Zetar Can Make It Come True.

From 3D Model to Mold Design

DFM Report, Mold Flow & Mold Design

-

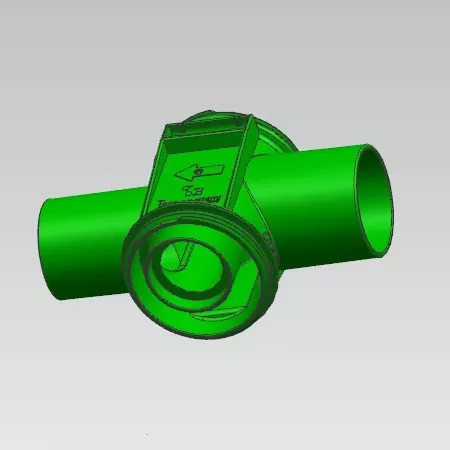

After prototype approved, Zetar will provide the detailed DFM report to you for conformation and then design the mold 3D drawing.

We will do model flow for some complex projects to evaluate the risks in the injection molding process , Each step will be presented to you as the schedule.

Basics of Injection Mold Design Process

Injection mold design process consists of 3 necessary steps:

- DFM Report: This report including part dimensions, injection ports, part lines, pin marks, draw angles and tolerances, and a list of materials to be used in the injection molding process.

- Mold Flow Analysis: It is a process that measures the way in which liquid flows through porous materials. This knowledge can be used to predict where liquid will leak, or what are the most critical areas of your system for maintenance purposes during manufacturing process.

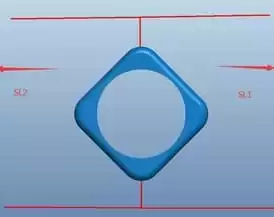

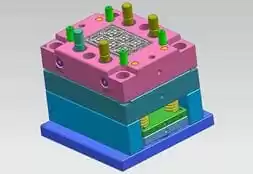

- Injection Mold Design: Designing a mold for manufacturing a plastic product as the DFM report and the mold flow analysis report.

What is DFM (Design For Manufacturing) Report

Table of Contents

A Design for Manufacturing (DFM) report is a document that outlines the feasibility of manufacturing a product through injection molding.

The report includes information on the design of the injection molded parts, including the dimensions, injection gate, part line, pin marks, draft angle and tolerances of the parts, as well as a list of the materials that will be used in the injection molding process. This article will describe what is included in the DFM report, the figure on the right is an overview.

What information you need to confirm in the DFM report

Choose the right material

Plastic injection molding is a process where molten plastic is injected into a heated steel mold that has been shaped to the desired part. Designers have to take many factors into consideration when designing product for this design process and manufacturing process.

Confirm the mold shrinkage rate of different materials

The mold shrinkage rate of different materials can be found in the Design for Manufacturing (DFM) report. The report includes a list of the materials that will be used in the injection molding process, including their respective mold shrinkage rates.

Define the location of the engraving and content

Different LOGO size and position require different mold processing technology to achieve. Some LOGO can use CNC processing, some LOGO need EDM processing. Determine the position and content of the engraving, mold maker can arrange a good processing plan in advance

Defines the surface treatment

The most common way to specify injection moulding surfaces is by using VDI, SPI, MT,and YS standards. Although the surface finish on any plastic injection-molded part might be perfectly suitable for its intended application, you should be aware that there is a range of available texturing options, all can be applied to certain areas of a mold or even the entire mold.

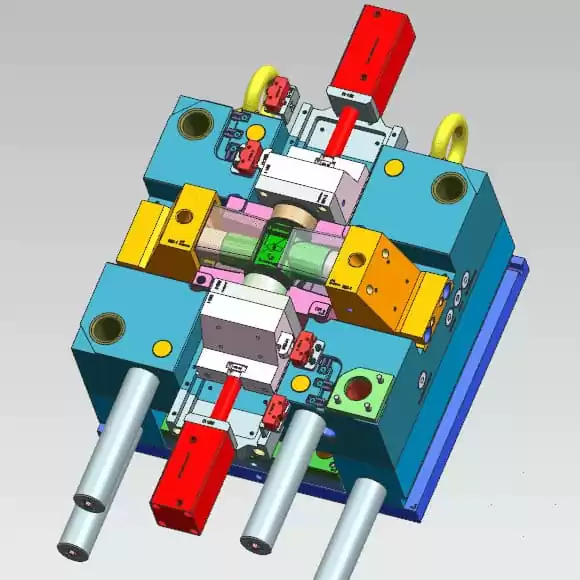

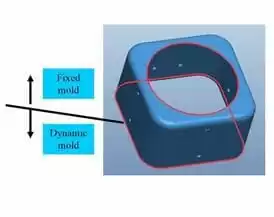

Confirm Mechanical structure / parting line

Briefly introduce the mechanical structure of the slider, lifter and so on used in the injection mold design. Make sure the parting line is accepted.

Because some structure of the sliders and lifts will have lines and demarcation lines which will affect the mold surface, so the designer needs to confirm with the customer whether it is acceptable or not, because it will cost a lot of money and time if the mold is done and then changed.

Runner type: cold runner or hot runner

When selecting a runner type for an injection mold, consider the following factors:

- The volume of plastic that will be injected into the mold

- The temperature of the plastic at the time of injection

- The size and shape of the runner system

Cold runners are best suited for low-volume production runs, while hot runners are better suited for high-volume production runs.

Confirm the mold cavities

The number of the cavities and mold construction depend on both economic and technical factors:

- The quantity of parts to be injection molded at one cycle

- The required cycle time

- The Tonnage of machine and unit price

- The mold making cost.

Confirm the mold cavities material

Any kind of product has a limited service life, and the mold is no exception. The cavities material is the 1st key point affecting the life of a mold.

Usually we consider the cavities material of the mold according to the output of the plastic injection molded parts, the surface treatment requirements and the material characteristics of the product, as well as the structure of the product.

Why We Do Mold Flow Analysis

Table of Contents

Mold flow analysis (MFA) software simulates the flow of plastic, which allows you to elevate part and injection mold design to create products of impeccable quality.

Mold flow analysis is a process that measures the way in which liquid flows through porous materials. This knowledge can be used to predict where liquid will leak, or what are the most critical areas of your system for maintenance purposes during manufacturing process. Knowing these things can help minimize development time and increase plant safety.

Predict potential design risks and create a successful mold from the start.

The Mold flow analysis software is not required for the plastic injection molding process. But maybe it should be, especially considering it can help to predict manufacturing issues before production starts. The mold flow analysis simulation software simulates an injection molding cycle using a specific plastic part design. It evaluates the design for manufacturability before cutting the injection mold.

Mold flow analysis can provide designers with the following references:

- Correct potential cosmetic and structural problems

- Determine optimal gate locations

- Adjusting adequate corner radii

- Determining the best material to achieve desired results

- Predict product surface shrinkage and air trapping

- Predicting filling times for the injection molding process

- Predict warpage of the product

- Adjusting the position of the product’s welding line

What we can get from mold flow analysis diagnostic reports

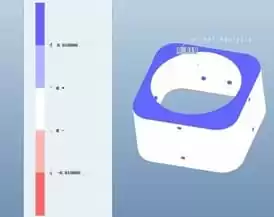

This mold flow analysis software creates color maps of different properties of the design as they would be reflected in the actual mold flow that simulate how the plastic behaves in the injection mold. The report includes :

Material flow direction

The material flow analysis direction is one of the most important pieces of data you can get from mold flow analysis report. This report shows you where the material is flowing in your mold during plastic injection molding processes, which can help product design to identify potential problems with your design. Shrinkage, deformation, air trapping, and bond line position can be controlled and adjusted by adjusting material flow direction.

The designer evaluates the image for flow paths that finish and reach the edges at the same time. Evenly spaced contours indicate the speed at which the plastic is flowing. Widely spaced contours indicate rapid flow; narrow contours indicate the molded part is filling slowly.

Material temperature change during injection molding process

In the injection molding process, as the injection material flows in the tooling, the temperature will get lower and lower, the lower the temperature of the material, the slower the flow of the material. It will cause problems such as obvious welding line and lack of material.

The designer can analyze the temperature change to decide whether to increase the number of injection gate, increase the size of the injection gate, change injection gate placement, etc.

Injection pressure

In the production process, injection pressure control within a certain range is beneficial to the life of the mold, especially for high-volume production projects. The injection pressure determines the clamping force, the clamping force determines the machine tonnage, and the machine tonnage then affects the production costs and production efficiency.

The designer can optimize the injection molding pressure to optimize the injection gate, product structure, and wall thickness, etc.

Filling time results

The filling time is related to the fluidity of the material, the temperature of the mold during injection molding, the injection molding pressure, the wall thickness of the product, and the structure of the product. In general, a shorter filling time is better because it results in less material waste. However, if the filling time is too short, it may cause problems such as flashing or sink marks.

The Fill Time Result report presents the position of the flow front at regular intervals as the mold cavity fills. A balanced flow of plastic pattern indicates the plastic part has a good fill time. The designer can adjust the fill time to find the best balance between material waste and quality defects.

The colors displayed in the Fill time results

- All green: Plastic fills the part easily and the part quality will likely be acceptable.

- Some yellow: The part can be difficult to mold, or quality is probably not acceptable. As the percentage of yellow increases, the difficulty in molding the part increases, and the part quality decreases.

- Some yellow and red: The part is difficult to fill, or quality is probably unacceptable. As the percentages of yellow and red increase, the difficulty in molding the part increase, and the part quality decreases.

- Any translucent: The part cannot be molded because a short shot will occur.

Welding lines

Welding lines form when the two halves of the mold come together. If the material isn’t able to fill the entire cavity, you’ll see a weld line where the two halves meet. Weld lines are usually cosmetic problems, but they can also cause structural problems. You can usually avoid welding lines by adjusting the position of the gate, increasing the size of the gate, or changing the material. Mold flow analysis can help you to determine if these adjustments will be effective.

Sink and warp

Sink and warp are the most common injection molding defects. The sink will occur when a material droops down from a surface. Warp happens when a material stretches outward from a surface. Both of these issues can be fixed by adjusting the clamping force, but they can also be fixed by adjusting or recommending different material options used or altering the design of the product.

Trapped air trap

Air traps are relatively common molding defects. What’s most important about air traps is how they’re created-a lack of proper flow will cause air bubbles to form at the surface of the plastic; these bubbles need to be removed in order to create a quality product.

Mold clamping force

Mold clamping force is the force that holds two mold halves together. It will determine the tonnage of the injection molding machine. The higher the pressure, the stronger the mold will be able to withstand. By adjusting the clamping force, you can adjust the temperature of the material, fill time, and other design factors.

Mold flow analysis: optimize the design before making the mold

Accurate mold tools are critical to producing high quality products, repeatable plastic parts. Mold flow analysis software can help mold design engineers to optimize the process before injection molder making the mold. This mold flow analysis software can be used to determine the optimum injection molding pressure, fill time, and other factors that will affect the quality of the parts. By adjusting these settings, you can minimize defects and produce a high quality products.

What You Need to Know About Injection Mold Design

Table Of Contents

Designing the right mold for your product is vital to its success. Plastic Injection mold tool design can be a difficult and time-consuming process, which is why it’s so important to get it right from the beginning. The Definitive Guide of Injection Molding Design: What You Need to Know will teach you all about injection molding designs, what goes into them, and how they’re made.

What is Injection Mold Design?

Injection mold design is the process of designing a mold for manufacturing a plastic product. The mold is used to create a cavity in which the plastic product is injected. This cavity is then cooled and the plastic product is removed.

Before mold design, what we should know?

Before designing a mold, there are some important things to know. The following is a list of the most important factors to take into account:

Injection Molded Part Drawings

Injection molded parts drawings should include product tolerances, material types, colors, and finishes. These factors will help the designer create a mold that produces the exact product for which it was made.

Type Of Material

Different injection molding materials have different shrink rates and material characteristics. This means that the mold must be designed differently depending on the type of material that will be used. For example, a mold designed for use with ABS plastic will not work correctly with PP plastic material.

Injection Molding Machine Technical Specs

Decide on which injection molding machine type best suits your needs and gather data about available machines with a similar setup.The injection molding machines technical specs are an important consideration when designing a mold. The machine must be able to produce enough pressure to inject the plastic into the cavity. It must also be able to heat the plastic to the correct temperature.

The Quantity Of Products

In order to balance the cost, the injection mold tool designer decides the number of mold outs and the choice of mold material according to the number of plastic parts. For a small quantity of products, less expensive injection molding material can be used, such as aluminum, S45C or S50C. However, for large quantities, a more durable and expensive plastic resin material, such as 2738,NAK80,H13, S136 is necessary. The number of mold outs will also affect the production costs. A higher number of mold outs will require a more expensive material and result in a higher cost.

What are the specific requirements for the mold design?

The Example of Mold Design Process?

| Part Name | Material | Shrinkage | Surface Treatment | Cavity | Runner Type | Mold Type | Cavity Material |

|---|---|---|---|---|---|---|---|

| COVER08 | PC | 1.005 | SPI-A3 | 1*8 | Hot Runner | Two Plate Mold | NAK80 |

The purpose of mold design: to save costs and improve productivity

Every industry is facing fierce competition these days, and the plastic injection molding sector has been no exception. The cost of molds have rise to great concern for any mold designer who strives in this field as they must consider how lower it while ensuring high efficiency with every injection molding design process that enters into mass production–a task not an easy one by any means!

I hope this article has helped you learn about injection mold design. If you’re in need of any assistance, feel free to contact us here by email: [email protected]

Our expertise is here to serve you

phone

0086-13564311131

Sales Office: No.29 Moyu Road, Jiading District, Shanghai, China

Shanghai Factory Address: No.998 Huazhi Road, Qingpu District, Shanghai, China

Jiangsu Factory Address: No.777, Jimingtang South Road, Kunshan City, Jiangsu Province

Zhejiang Factory Address: No.1 Xingcheng Road, Yuyao City, Zhejiang Province

Zetar Industry Co.,Ltd

phone

0086-21-64028287