In the plastic injection molding design, in addition to the general mold design matters, the following matters should also be considered:

- To obtain the product with the required dimensional tolerance, the appropriate mold dimensional tolerance should be considered

- Consider preventing fluctuations in injection molding shrinkage

- Consider preventing molding deformation

- Consider preventing mold release deformation

- To minimize the mold-making error

- It is necessary to consider preventing the fluctuation of mold accuracy

Proper die size and tolerance

1.1 The relationship between product dimensional accuracy and mold dimensional accuracy

Draw product drawings, consider mold design, injection mold making, and molding process. First, the mold drawing size can be obtained from the product drawing size.

Make a mold according to the size of the mold drawing to get the actual size of the mold.

Using this mold, a shaped product can be obtained, and the actual size of the product can be obtained. The question is how can this actual size be within the desired dimensional tolerance of the drawing.

1.2 Appropriate shrinkage

As described above, even in the same resin using the same pigment, the shrinkage rate varies depending on the molding conditions.

In precision injection molding, the degree of shrinkage change should be small, and the expected shrinkage and actual shrinkage should be as indistinguishable as possible.

It mainly uses the actual shrinkage rate of similar products in the past to estimate the shrinkage rate, also uses the experimental mold to find the actual shrinkage rate, and then corrects and designs the production mold.

However, it is almost impossible to accurately estimate the shrinkage rate, and it is inevitable to correct the mold after the trial molding. As a result of the correction, the concave part will increase in size and the convex part will decrease in size.

Therefore, the shrinkage ratio is set to a small value for the concave portion size, and the shrinkage ratio is set to a large value for the convex portion size.

When the outer diameter of the gear becomes larger, it cannot mesh, and when it becomes smaller, only the backlash becomes larger, so the shrinkage ratio should be set to a small value.

Prevent the fluctuation of molding shrinkage rate

Precision injection molding process must be based on the premise that the mold can be made according to the desired size.

However, even if the mold size is constant, the actual size of the product varies due to the actual shrinkage. Therefore, in precision injection molding, the control of the shrinkage rate is very important.

The appropriateness of the injection mold design governs the shrinkage rate, which also varies from batch to batch of resin, and the shrinkage rate also varies if the pigment is changed.

Depending on the The precision injection molding machines, the setting of molding conditions, the reproducibility, and the action of each injection molding cycle fluctuate, and the actual shrinkage rate fluctuates, so shrinkage control is difficult.

The main factors affecting the shrinkage rate

The size of the mold can be obtained by adding the size of the product to the shrinkage rate, so when designing the mold, the main factor of the shrinkage rate needs to be considered.

The main factors affecting the molding shrinkage rate are:

(1) Resin pressure

(2) Resin temperature

(3) Mold temperature

(4) Gate cross-sectional area

(5) Injection time

(6) cooling time

(7) product wall thickness

(8) reinforcing material containing basin

(9) Orientation

(10) injection speed

These effects vary with changes in items such as resin and molding conditions:

(1) Resin pressure

The resin pressure has a great influence on the shrinkage rate. If the resin pressure is large, the shrinkage rate becomes smaller and the product size becomes larger.

Even within the same cavity, the resin pressure varies depending on the shape of the product, resulting in a difference in shrinkage.

In the case of a multi-cavity mold, the resin high pressure in each mold cavity is likely to vary, and as a result, the shrinkage rate of each injection mold cavity is also different.

(2) Mold temperature

Regardless of whether it is an amorphous resin or a crystalline resin, if the mold temperature is high, the shrinkage rate will increase.

Precision injection molding needs to maintain the mold temperature at a specific temperature. When designing the mold, attention must be paid to the cooling circuit design.

(3) Gate cross-sectional area Generally speaking, when the gate cross-sectional area is changed, the shrinkage rate also changes. The shrinkage rate decreases as the gate size become larger, which is related to the fluidity of the resin.

(4) Product wall thickness

The wall thickness of the product also affects the yield. For non-crystalline resins, the shrinkage rate of the resin on the wall thickness tends to be different. The larger the wall thickness, the larger the shrinkage rate.

On the contrary, the shrinkage rate becomes smaller. For crystalline resins, particularly large variations in wall thickness must be avoided. In the case of a multi-cavity mold, if the cavity wall thickness is different, the shrinkage rate will also be different.

(5) Reinforcing material content

When the resin is reinforced with glass fiber, the more glass fiber is added, the smaller the shrinkage rate will be. The shrinkage rate in the flow direction is smaller than the transverse shrinkage rate. Shape fly gate location and number of gates.

(6) Orientation

Although there are large differences in orientation, orientation exists for all resins. The orientation of crystalline resins is particularly large and varies depending on the wall thickness and injection molding conditions.

In addition, there is shrinkage after molding. The main factors affecting shrinkage after molding are:

1. Internal stress relaxation

2. Crystal

3. Temperature

4. Humidity

Actions that can be taken

Runner, gate balance

As mentioned above, the shrinkage ratio varies with the resin pressure. In the case of single-cavity molds with multi-point gates and multi-cavity molds,

To perform the same filling, gate balancing is required. Resin flow is related to the flow resistance in the runner, so it is best to balance the runner before balancing the gate.

Cavity arrangement

To make the setting of molding conditions easy, it is necessary to pay attention to the arrangement of the cavities.

Since the molten resin heats the mold, in the case of a general cavity arrangement, the injection mold temperature distribution is concentric with the gate as the center.

Therefore, when choosing the arrangement of the cavities of the multi-cavity mold, it is not only easy to balance the runners, but also to take the concentric arrangement with the gate as the center.

Prevent molding deformation

The cause of forming deformation is internal stress under uneven shrinkage, so it is necessary to prevent uneven shrinkage. In the case of a circular product with a hole in the center of the gear, a gate must be placed in the center.

However, when the resin flow direction is significantly different from the vertical shrinkage rate, it has the disadvantage of generating an ellipse. When the temperature is high, it needs to be set to a 3-point or 6-point gate.

However, it is necessary to pay full attention to the balance of each gate. When using a side gate, the 3-point gate will increase the inner diameter of the cylindrical product, and if the gate traces are not allowed on the outer mold surface and end face, the inner multi-point evenly divided gate can be used less, and good results can be obtained.

Prevent deformation from demolding

Precision products are generally small, the wall thickness of the product is thin, and some have many thin ribs.

The design of the chess set must be considered so that the product is not deformed and can be properly removed. For resins with less shrinkage.

When the molding injection pressure is high, it should be noted that the product is easy to stay in the mold cavity.

When molding the gear with resin with low shrinkage, it is better to design the cavity of the gear part on the template on the eject side.

When using the ejector pins, it is necessary to pay attention to the number of ejector pins without deformation and the position of the ejector pressure.

Gears with holes require core pins, and in this case, to facilitate parallel ejection during ejection, they need to be installed on the ejector side template.

For angular products, a punching template can be used for ejection, which can prevent deformation. Generally, the draft angle of precision products is small.

To reduce the demolding force, mirror finishing is required, and the grinding direction must be the drafting direction. Block cores that are easy to grind should be provided in the direction of the draft.

Minimum mold-making an error

5.1 Appropriate mold construction according to the processing mode

To obtain the desired precision of the product size, the corresponding mold size must be available, and the mold needs to be processed with extremely high precision, and the processing machinery limits.

To maintain the precision of the die, high wear resistance is needed, so quenching is needed. The precision of quenching die machining by grinding machine and EDM machine can be less than 0.01 mm.

When machining the red dean of the EDM machine, it is necessary to pay attention to the wear of the electrode end.

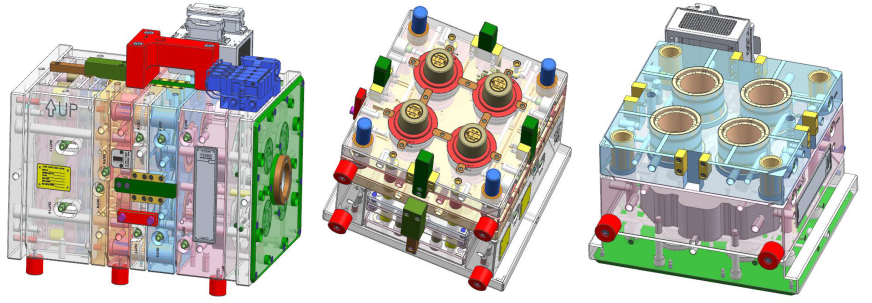

When machining the cavity of the gear in FIG. 3 and the wire EDM machine, the structure that can be cut through the machining should be designed as far as possible to prevent grinding deformation and shorten the processing time.

The steel with less quenching deformation should be selected, and the shape with less quenching deformation should be designed. When the shape is complex, you will not cool evenly, easy to produce quenching deformation.

5.2 General split mold

To process the quenched parts to a higher precision, a grinder is used. Therefore, it is necessary to use inserts to form a segmented mold.

The mold hasmoldfollowing features:

(1) Because appropriate materials can be selected, appropriate hardness mold materials can be used.

(2) Mold materials with high corrosion resistance and wear resistance can be used.

(3) It can be heat treated separately, so it is easy to set heat treatment conditions.

(4) It can use mirror processing good mold materials, mirror the cessing operation is easy, so can improve the mirror degree.

(5) Because it is easy to grind in the direction of the drawing die, it is conducive to the use of the injection mold with a small inclination of the drawing die.

(6) Due to hardening, it can prolong the precision keeping time of the mold, and the mold life is long.

(7) Easy to set the exhaust at any position, so easy to fill the mold.

(8) The grinding process is easy.

(9) It can improve the precision of injection molded parts, so it may improve the precision of products.

(10) Spare cavity and core can be made within a small tolerance, so the parts have high interchangeability and easy maintenance.

(11) Because the grinding process is the main body, so the processing efficiency is high.

(12) The number of parts, is necessary to greatly improve the machining accuracy of each part.

(13) Limited to specific processing methods

(14) Adopt complete quenching

To prevent the error in mold accuracy

To ensure the positioning of sliding parts in each cycle, it is necessary to prevent fluctuations in die accuracy.

To maintain the accuracy of the slide, the slide should be catenated. The sliding part of the side core should be matched with the positioning and withdrawal part.